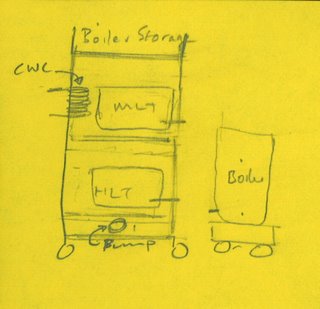

Aussiehombrewer Advice

Stuck Runoff

Lose the Braid!

Thursday, April 27, 2006

Wednesday, April 26, 2006

ANZAC Day Brew PITA

The new setup worked out fairly flawlessly to a point - more later.

Quite a bit of temp loss in the hoses and the fittings - Water at 80C in the boiler dropped to about 70 in the MLT! A couple of quick kettles of water were required to get the temp up. Next time may run some hot water in to heat it up or just allow for more of a differential.

During the sparge sterilsed the chiller by pumping the 80-90c water up to the HLT via it. Had previously done a poor man's CIP routine with dishwasher powder in hot water followed by a rinse.

Boiled fine - a little too fine towards the end - lost a few litres over the top!

Then the runoff to the fermenter! Whirlpooled, waited a bit a turned the pump on. All went well for a few minutes then it slowed to a trickled. Stop, whirlpool, wait, try again. Ended up turning the pump off and letting gravity do the work. Persisted with "runoff" for a couple of hours then at the recommendation of the assistant brewer gave up o the last 10 litres (still got 40-45).

Subsequent look at the bottom of the boiler confirmed that the braid on the pickup tube which was supposed to filter was solid with pellet residue. Will need to lose the braid and try something more open - suggestions?

The new setup worked out fairly flawlessly to a point - more later.

Quite a bit of temp loss in the hoses and the fittings - Water at 80C in the boiler dropped to about 70 in the MLT! A couple of quick kettles of water were required to get the temp up. Next time may run some hot water in to heat it up or just allow for more of a differential.

Mash settled in at 63c and held within a couple degrees for the 120 min it was there.

Sparge went flawlessly - quick recirc with the pump then slow drain into the boiler with slow top up from HLT above. Added the Roasted Barley about half way through the sparge - had steeped in cold water over night per Tom's suggestion.During the sparge sterilsed the chiller by pumping the 80-90c water up to the HLT via it. Had previously done a poor man's CIP routine with dishwasher powder in hot water followed by a rinse.

Boiled fine - a little too fine towards the end - lost a few litres over the top!

Then the runoff to the fermenter! Whirlpooled, waited a bit a turned the pump on. All went well for a few minutes then it slowed to a trickled. Stop, whirlpool, wait, try again. Ended up turning the pump off and letting gravity do the work. Persisted with "runoff" for a couple of hours then at the recommendation of the assistant brewer gave up o the last 10 litres (still got 40-45).

Subsequent look at the bottom of the boiler confirmed that the braid on the pickup tube which was supposed to filter was solid with pellet residue. Will need to lose the braid and try something more open - suggestions?

Tuesday, April 25, 2006

Monday, April 24, 2006

Friday, April 21, 2006

Thursday, April 20, 2006

Virgin Stout

Thinking of a Guiness clone for the first run with the new system.

11kg of Pale, 1.3 of Roast Barley, 1.3 flaked Barley to make about 55 litres. Hops TBA.

Still need to delead the brass fittings in Hydrogen Peroxide and Vinegar.

May subsequently try to lock up the lead with ortho phosphoric acid - they do this in water systems so can't hurt.

Thinking of a Guiness clone for the first run with the new system.

11kg of Pale, 1.3 of Roast Barley, 1.3 flaked Barley to make about 55 litres. Hops TBA.

Still need to delead the brass fittings in Hydrogen Peroxide and Vinegar.

May subsequently try to lock up the lead with ortho phosphoric acid - they do this in water systems so can't hurt.

Tuesday, April 18, 2006

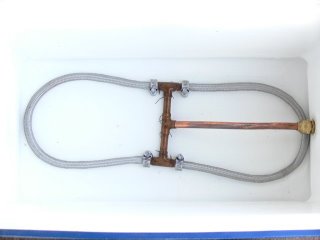

The Counterflow Chiller - Wort through the central 1/2 inch tube and cooling water going the other way through the 18mm hose the contains it.

Counterflow Chiller - Wort through the central 1/2 inch tube and cooling water going the other way through the 18mm hose the contains it.

Heard of Phil's Fittings? - this is a Bill's Fitting.

Heard of Phil's Fittings? - this is a Bill's Fitting.

20mm x 15mm x 15mm T piece. Had to solder a 3/4 stub in the right port and 1/2 in the top to connect the CW hoses.

Initially tried soldering the left hand port to the 1/2 tube that runs from left to right but the heat started melting the hose on the right. Ended up using some 1/2 vinyl in some 3/4 hose and a couple clamps to stop the drips - learning - don't bother soldering this, the two bits of hose and the clamps seem to be good enough (and you can pull it apart!)

Counterflow Chiller - Wort through the central 1/2 inch tube and cooling water going the other way through the 18mm hose the contains it.

Counterflow Chiller - Wort through the central 1/2 inch tube and cooling water going the other way through the 18mm hose the contains it. Heard of Phil's Fittings? - this is a Bill's Fitting.

Heard of Phil's Fittings? - this is a Bill's Fitting.20mm x 15mm x 15mm T piece. Had to solder a 3/4 stub in the right port and 1/2 in the top to connect the CW hoses.

Initially tried soldering the left hand port to the 1/2 tube that runs from left to right but the heat started melting the hose on the right. Ended up using some 1/2 vinyl in some 3/4 hose and a couple clamps to stop the drips - learning - don't bother soldering this, the two bits of hose and the clamps seem to be good enough (and you can pull it apart!)

Subscribe to:

Comments (Atom)